Coil Polyethylene Pipe PE HDPE LDPE PPR Plastic Water Gas Oil Supply Sewage Hose Pipe Tube Extrusion Production Line Single Screw Extruder Pipe Making Machine

Single Screw Extruder Pipe Machinery PE HDPE PPR Pipe Extrusion Production Line HDPE Pipe Application: Agricultural Irri;

Basic Info.

| Motor | Siemens |

| Inverter | ABB |

| Name | PE PP PPR Pipe Machine Production Line |

| Power Supply | 380V 3phase 50Hz (Can Be Customized) |

| Transport Package | PE Film and Wood Packaging |

| Trademark | YUREFON |

| Origin | Jiangsu, China |

| HS Code | 84772090 |

| Production Capacity | 5 Sets/Month |

Product Description

Single Screw Extruder Pipe Machinery PE HDPE PPR Pipe Extrusion Production LineHDPE Pipe Application:

Agricultural Irrigation water supply&Sweage drainage pipe&Discharge system&Gas supplly system&Architectural water supply.

Production Flow of Pipe Production Line:

Material →Color Mixer →Automatic Feeder→Hopper Dryer →Single Screw Extruder →Extrusion Mould & Calibrator → Vacuum Calibration Cooling Tank → Spray Cooling Tank →Printer → Haul-off Unit →Cutter →Stacker or Coiler

Features of Pipe Machiner:

1- 30m/min of maximum lineal extrusion speed, big capacity and low power consumption, and achieved multi- layers co extrusion with 1-5 layers.2- The copper bush is more wear-resisting and prevent material leakage which can guarantee a stable running of extruder. 3- Material feed via spiral groove, efficient transmission and can effectively reduce back-pressure on extruder.4- Unique design (barrier, shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and stable output capacity.5- High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation;6- PCA(pipe air cooling system) of die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe surface;7- Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently;8- Chip-free cutter ensuing flat and smooth cutting surface of pipe.

Main Technical Parameter:

| Machinemodel | Pipe diameter | Vacuum Calibration Tank | Spray Cooling Tank | Haul-off unit | cutter | ||||

| Vacuum pump | Water pump | Length(mm) | Waterpump | Length(mm) | Caterpillar Quantity | Motor | Cutting type | ||

| HDPE-630 | Φ250mm-φ630mm | 7.5kw*2 | 7.5kw*2 | 6000mm | 7.5kw*1 | 6000mm | 6 | 1.1kw*6 | Planetary cutter |

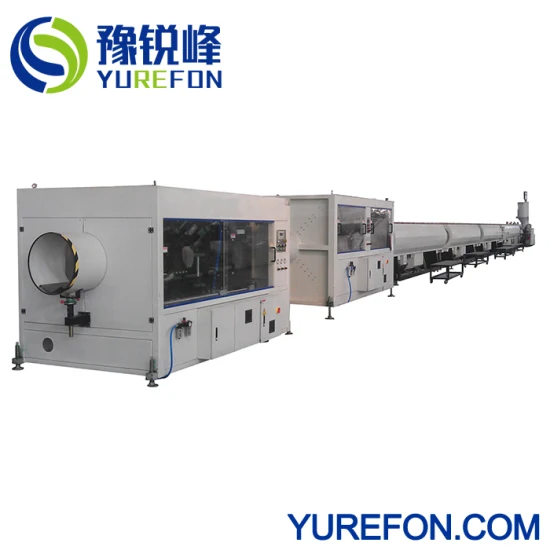

Machine picture:

Extrusion machine

Vacuum Calibration Cooling tank & Spray Cooling tank

Six Claw Haul-off unit

Planetary Auto-Cutter

Plastic Pipe Stacker

If you have any questions, please contact us:

You may also like

Send inquiry

Send now